Rubber gasket sheets are versatile materials that offer several benefits in a wide range of industrial and commercial applications. Here are some of the key advantages of using rubber gasket sheets:

- Sealing Properties: Rubber gasket sheets are known for their excellent sealing capabilities. They can effectively create a watertight and airtight seal, preventing the leakage of fluids, gases, or contaminants.

- Temperature Resistance: Rubber gasket sheets are available in various formulations that offer good resistance to temperature extremes. They can withstand both high and low temperatures, making them suitable for applications in extreme environments.

- Chemical Resistance: Depending on the specific rubber material used (e.g., neoprene, EPDM, Viton), rubber gasket sheets can offer resistance to various chemicals, oils, solvents, and acids. This chemical resistance makes them ideal for applications where exposure to harsh substances is common.

- Durability: Rubber gasket sheets are durable and have a long service life, even when exposed to harsh conditions. They are resistant to degradation from UV radiation, ozone, and weathering.

- Easy Installation: Gasket sheets are relatively easy to cut and shape into the desired form. This makes installation straightforward, and they can be custom-fitted to the specific requirements of the application.

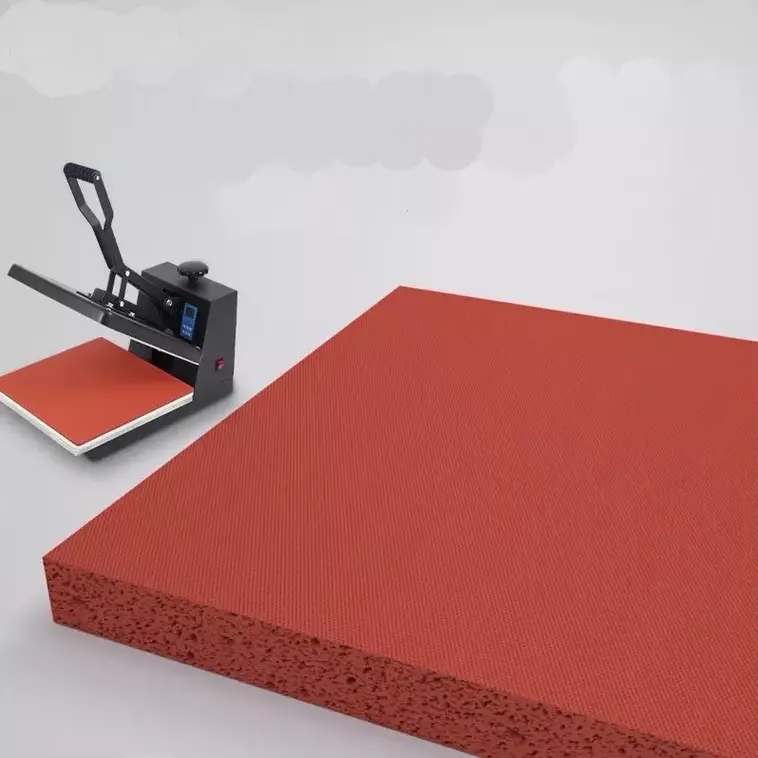

- Vibration and Shock Absorption: Rubber gaskets have natural vibration-dampening properties. They can help reduce the impact of vibrations and shocks in mechanical systems, which can extend the life of components and equipment.

- Electrical Insulation: Some rubber materials, such as silicone, offer excellent electrical insulation properties. This makes them suitable for sealing electrical enclosures and components.

- Sound Dampening: Rubber gaskets can help reduce noise transmission, making them useful in applications where sound insulation is needed, such as in automotive and HVAC systems.

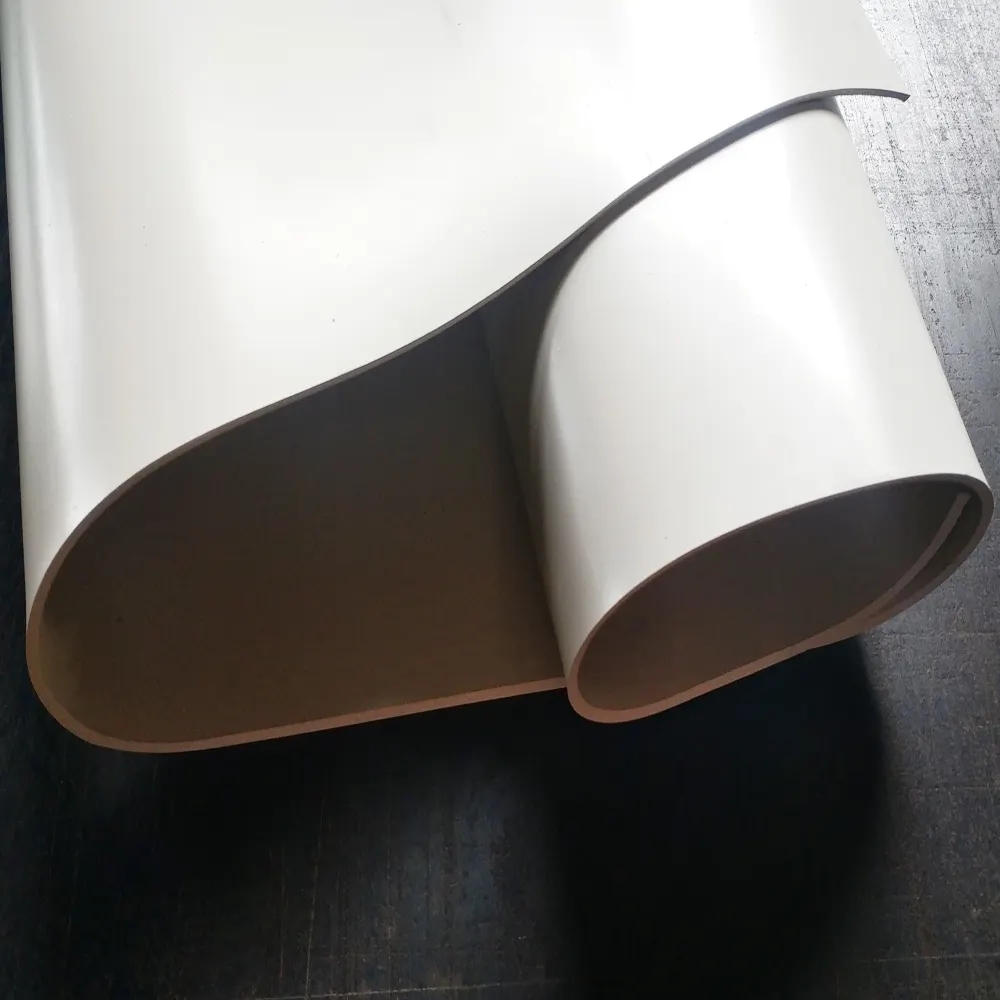

- Flexibility: Rubber gasket sheets are flexible and can conform to irregular surfaces, ensuring a tight seal, even on uneven or non-uniform mating surfaces.

- FDA Approval: Certain types of rubber gasket materials, like silicone, have FDA approval for use in food and pharmaceutical applications. This is important for applications that require compliance with regulatory standards.

- Cost-Effective: Rubber gasket sheets are often a cost-effective solution compared to custom-molded gaskets, especially for low- to medium-volume production runs.

- Environmental Resistance: Rubber gasket sheets are resistant to environmental factors such as moisture, humidity, and mildew, making them suitable for outdoor and wet conditions.

- Wide Range of Material Options: There are various rubber materials available, each with its own set of properties and advantages, allowing you to choose the one that best suits your specific needs.

In summary, rubber gasket sheets are a versatile and reliable choice for creating seals in a variety of applications due to their sealing capabilities, resistance to temperature and chemicals, durability, and ease of installation. The specific benefits will vary depending on the type of rubber material used and the application in question.

Packaging methods for rubber gasket sheets are designed to protect the material during storage, handling, and transportation while also making it easy for customers to access and use the product. Here are some common packaging methods for rubber gasket sheets:

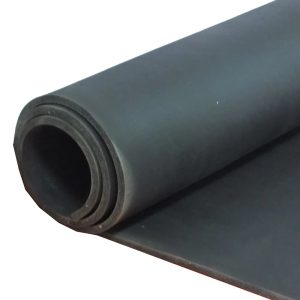

- Rolls: Rubber gasket sheets are often rolled up and packaged in rolls. This is a convenient way to store and transport the material, especially when it needs to be cut into custom lengths. Rolls are typically secured with bands or plastic wrap to keep the material tightly wound and prevent it from unrolling during transit.

- Sheets: Rubber gasket sheets can be packaged in individual sheets, typically stacked on top of one another. Sheets may be separated by interleaving paper or plastic sheets to prevent sticking between layers and to protect the surfaces of the gasket material from damage or contamination.

- Cut Gaskets: In some cases, rubber gasket sheets are pre-cut into specific gasket shapes and sizes to match the requirements of the application. These cut gaskets are often packaged individually or in sets, with each gasket typically separated by a layer of protective material.

- Bulk Packaging: For large quantities of rubber gasket sheets, they may be packaged in bulk. This could involve stacking multiple sheets or rolls together and securing them on pallets or in large containers. Bulk packaging is common for industrial customers with high-volume needs.

- Reels or Spools: Thin rubber gasket materials, such as silicone or foam gaskets, can be packaged on reels or spools, similar to the way electrical wiring or tape is packaged. This method is suitable for materials that are continuous and may need to be dispensed in a controlled manner.

- Custom Packaging: Depending on the specific requirements of the customer or application, rubber gasket sheets can be custom-packaged. This might include special packaging materials, labeling, or branding to meet unique needs.

- Vacuum-Sealed Bags: Some rubber gasket sheets, especially those sensitive to moisture and environmental factors, are vacuum-sealed in plastic bags. This helps maintain the material’s integrity and prevents it from being exposed to moisture and contaminants.

- Laminated Packaging: Rubber gasket sheets may be laminated between layers of protective films or foils. This laminated packaging method provides extra protection and helps keep the gasket sheets clean and free from damage.

- Protective Boxes or Cartons: For individual gasket sheets or sets of cut gaskets, protective boxes or cartons can be used. These boxes provide additional protection and make it easier to handle and store the gaskets.

The choice of packaging method depends on factors such as the type of rubber gasket material, the size and quantity of the sheets, and the specific requirements of the customer or application. Packaging should be designed to preserve the quality and integrity of the rubber gasket sheets until they are ready for use.

Rubber gasket sheets offer several advantages due to their unique properties and versatility. Here are some of the key advantages of using rubber gasket sheets:

- Excellent Sealing Properties: Rubber gasket sheets are known for their superior sealing capabilities. They can create a tight and reliable seal, preventing the leakage of gases, liquids, and contaminants.

- Wide Temperature Range: Rubber gasket sheets are available in various formulations, which provide them with a broad temperature resistance range. They can perform effectively in both high and low-temperature environments.

- Chemical Resistance: Depending on the specific rubber material used (e.g., neoprene, EPDM, Viton), rubber gasket sheets can offer resistance to a wide range of chemicals, oils, solvents, and acids. This chemical resistance makes them suitable for applications where exposure to corrosive substances is common.

- Durability: Rubber gasket sheets are durable and can withstand harsh environmental conditions. They are resistant to UV radiation, ozone, weathering, and wear and tear.

- Flexibility and Conformability: Rubber gasket sheets are flexible and can conform to irregular or non-uniform surfaces, ensuring a tight seal even on uneven mating surfaces.

- Vibration and Shock Absorption: Rubber gaskets have natural vibration-dampening properties, which help reduce the impact of vibrations and shocks in mechanical systems, thereby extending the life of equipment and components.

- Electrical Insulation: Certain rubber materials, like silicone, provide excellent electrical insulation properties, making them suitable for sealing electrical enclosures and components.

- Sound Dampening: Rubber gasket sheets can help reduce noise transmission, making them valuable in applications where sound insulation is needed, such as automotive and HVAC systems.

- Easy Installation: Rubber gasket sheets are easy to cut and shape into the desired form, simplifying installation. They can be customized to fit specific application requirements.

- FDA Approval: Some rubber materials, such as silicone, have FDA approval for use in food and pharmaceutical applications, ensuring compliance with regulatory standards.

- Cost-Effective: Rubber gasket sheets are often a cost-effective solution compared to custom-molded gaskets, especially for low to medium-volume production runs.

- Environmental Resistance: Rubber gasket sheets are resistant to environmental factors such as moisture, humidity, and mildew, making them suitable for outdoor and wet conditions.

- Variety of Material Options: There are various rubber materials available, each with its own set of properties and advantages, allowing you to choose the one that best suits your specific needs.

In summary, rubber gasket sheets are a versatile and reliable choice for creating seals in a variety of applications due to their sealing capabilities, temperature resistance, chemical resistance, durability, flexibility, and other beneficial properties. The specific advantages will vary depending on the type of rubber material used and the application in question.