Quality Rubber Gasket Manufacturer You Can Rely On

When you’re in need of a quality rubber gasket manufacturer, reliability is of utmost importance. The right manufacturer should provide consistent quality, timely delivery, and responsive customer support. Here are key qualities to look for in a rubber gasket manufacturer you can rely on:

- Reputation and Experience: Choose a manufacturer with a strong reputation and a history of producing high-quality rubber gaskets. Look for reviews, testimonials, and their track record in the industry.

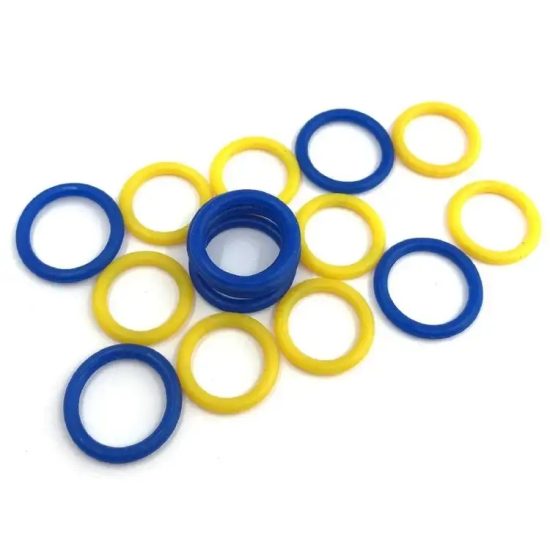

- Customization: A reliable manufacturer should offer customization options to tailor gaskets to your specific requirements. This includes variations in size, shape, and material composition.

- Material Expertise: The manufacturer should have expertise in a wide range of rubber materials. They should recommend the most suitable material for your application, taking into account factors like temperature resistance and chemical compatibility.

- Quality Control: Look for information on the manufacturer’s quality control processes. A reliable manufacturer should have strict quality assurance measures in place to ensure that their gaskets meet industry standards.

- Industry Compliance: Check if the manufacturer’s gaskets adhere to industry standards and regulations, especially if your application requires compliance with specific standards.

- Technical Support: A dependable manufacturer provides technical support and guidance to help you select the right gasket for your application. Their expertise is crucial in ensuring you choose the best sealing solution.

- Communication and Responsiveness: Assess the manufacturer’s communication and responsiveness. They should be easy to reach, responsive to inquiries, and capable of providing timely updates on your order.

- Samples and Prototypes: If possible, request samples or prototypes to evaluate the quality and fit of their gaskets in your application before placing a larger order.

- Lead Times and Shipping: Inquire about lead times for production and shipping. A reliable manufacturer should provide clear information on when you can expect to receive your gaskets.

- Cost Transparency: Request a detailed quote outlining the cost of the gaskets, any customization fees, and shipping charges. Ensure that the pricing is competitive and transparent.

- Environmental Responsibility: Consider whether the manufacturer follows environmentally responsible practices, such as using eco-friendly materials and sustainable manufacturing processes.

- Consistency and Reliability: A dependable manufacturer should consistently deliver high-quality gaskets that meet your specifications and performance expectations.

- Innovation: Look for a manufacturer that invests in research and development to create innovative gaskets with advanced sealing technologies. This commitment to innovation can result in improved gasket performance.

By considering these factors and conducting thorough research, you can identify a quality rubber gasket manufacturer that you can rely on to provide reliable and effective sealing solutions for your specific applications.